Soldering may seem complicated and difficult but with a little practice it can become quite simple. Nothing can substitute experience when soldering, but our tips will help you master this technique quickly. So read on!

In this post we’ll take you through the various dos and don’ts you need to know about soldering.

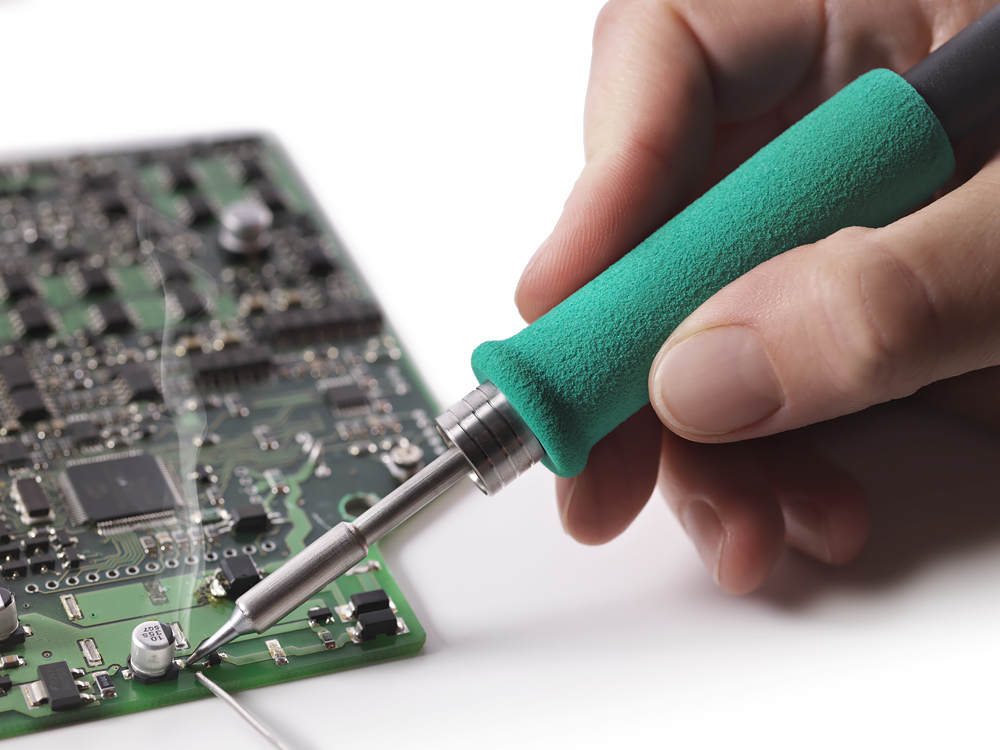

Be careful not to apply too much pressure

❌ Don’t apply too much pressure with the tool on the PCB or the parts being soldered. It will not solder the joints more quickly and will only damage the long-lasting plating and even ruin the finest tips.

✔️

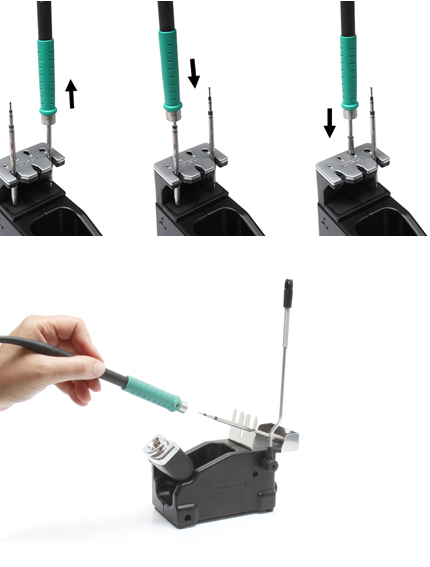

Return the tool to the stand

❌ Don’t leave your tool unattended when it is on. This can cause accidents and may damage the tool itself.

✔️ Always return the tool to the stand when not in use.

Use the cartridge extractor

❌ Don’t use a pliers or any other tool to remove and replace the cartridges. Don’t adjust or tighten the cartridge by using another surface other than the extractor. This can damage the tips irreparably.

Maintain tip surface clean

❌ A dirty rusty surface will not transfer the heat properly.

✔️ Keep the tips clean and re-tin them before placing the tool in the stand.

❌ Don’t use sandpaper or files to clean the tip.

✔️ Only use the cleaning methods provided by the manufacturer.

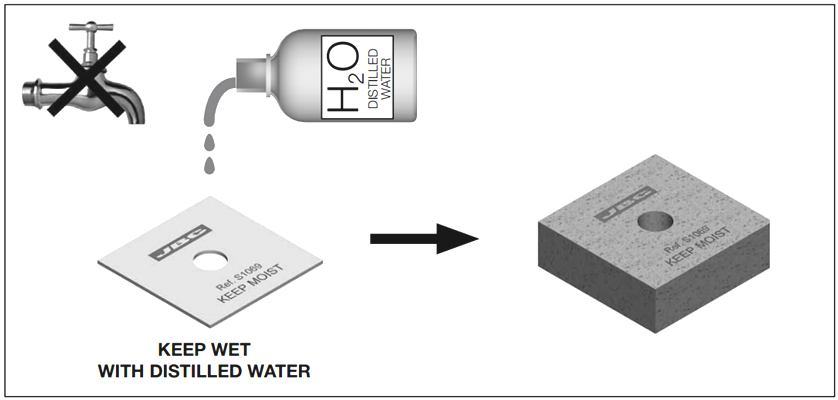

✔️ A damp (not swamped) sponge is an efficient cleaning method if it is kept clean. It should be changed periodically and only used with de-ionized water.

✔️ A damp (not swamped) sponge is an efficient cleaning method if it is kept clean. It should be changed periodically and only used with de-ionized water.

❌ Don’t use tap water under any circumstances.

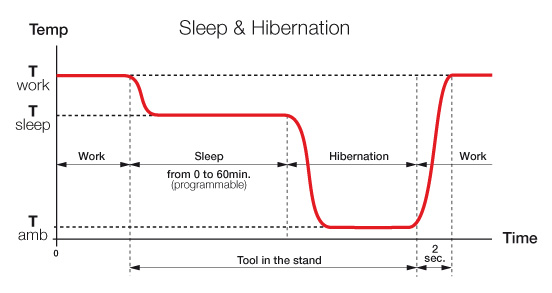

Take advantage of SLEEP & HIBERNATION modes.

❌ Don’t leave the tool at working temperature when in the stand.

✔️ Sleep & Hibernation functions automatically reduce tip temperature when the iron is at rest in the stand. This prevents rusting or oxidation.

Choose the correct soldering tip

✔️ Always choose the largest tip possible for each solder joint. Select the tip that has the greatest contact area.

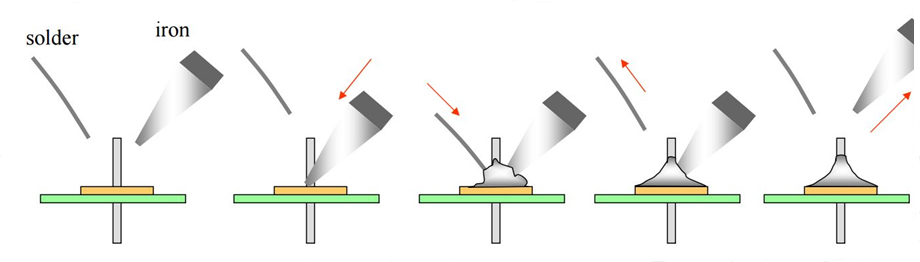

How to apply solder

❌ Don’t melt solder directly onto the tip unless necessary.

✔️ The solder wire should be applied to the surfaces being soldered. The diameter of the wire used must match the solder joint you are doing.

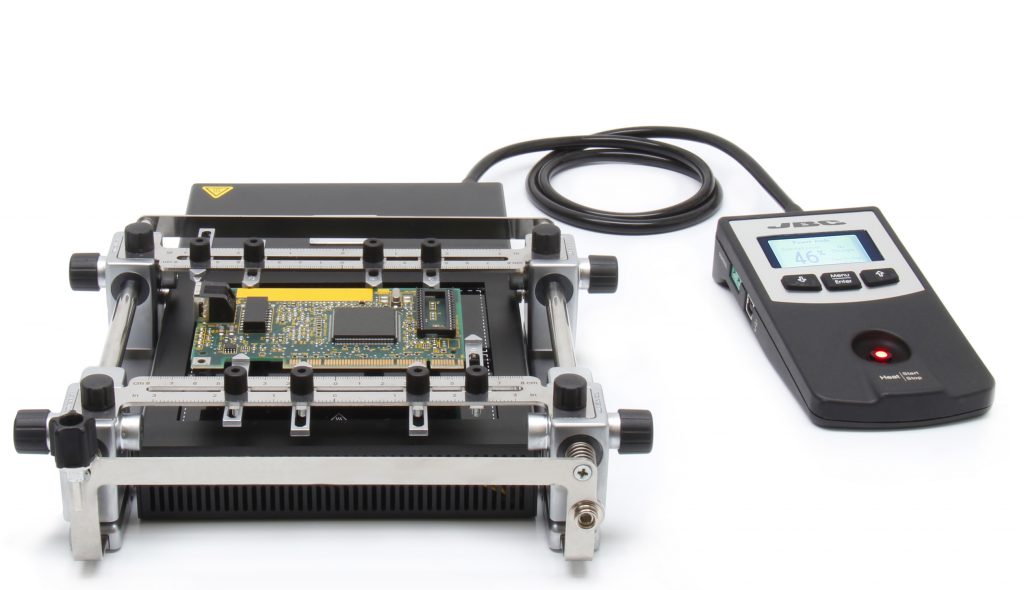

Work at the lowest possible temperature.

❌ The higher the temperature, the greater the risk of oxidation. A high temperature can damage the PCB and shorten the life of the tips.

✔️ 90% of solder joints using JBC tools can be performed successfully at 350°C or less. When the solder joint needs a temperature above 380°C, we recommend you use a preheater.

Avoid corrosion

❌ Don’t use too much active Flux. Excessive use can cause corrosion.

✔️ IPC recommends: ROL, REL and ORL. The internal flux from small Ø solder reels might not be enough. You can add compatible external Flux if necessary.

What other dos and don’ts can you think of?

Tell us in the comments section!

I like the post because all the Dos and Don’ts of soldering are explained with the help of image which is easy to understand for anyone.

We are glad to hear that you find it useful!

Great article, explained with clarity! cheers

Thanks, Jake! Comments like yours encourage us to continue writing 🙂

I love this fruitful content and hope people are also enjoying with this. Thanks for sharing this informative content about Soldering Iron,

Thanks, your information is actually very helpful for everyone related to soldering, especially do’s and don’ts containing the cleaning tips of soldering iron which we generally don’t follow unless we face such problem.

Dear Betty,

Thank you for your message. Your opinion is very important to us.

Please feel free to contact us anytime.

Nice! Thanks for sharing this fruitful content.

Thank you for your feedback