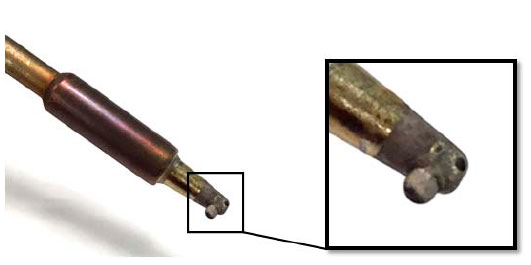

You are ready to start a soldering job: PCB and electronic components are clean and free from any contamination; you have a good quality solder flux; the most efficient tip has been chosen… but suddenly realize that oxidation has appeared due to an incorrect maintenance of the tip and the equipment.

What can you do to remove it? Just follow these steps according to the amount of rust!

Procedure to remove mild oxidation

- Set the temperature of the soldering iron between 250°C and 300°C.

- Apply the flux cored solder wire used in the assembly process onto the oxidized surface. The recommended temperature range of 250°C to 300°C will allow the flux of the solder to be activated (not burned) and will start the chemical reaction to remove the oxidation.

- Clean the tip using dry cleaning systems like brass wool or Automatic tip cleaners. The contact of the tip with the wool or the brushes will start to remove the oxidation from the surface.

Repeat steps 2 and 3 until the oxidation has been completely removed and the tip shows a good wetting on all its working area. It should not be necessary to repeat the operation more than 3 or 4 times to completely remove oxidation on a mildly oxidized tip.

Procedure to remove severe oxidation

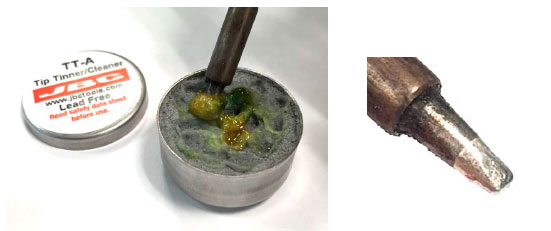

When the tip has been subjected to severe oxidation, the procedure for mild oxidation removal might not be sufficient to recuperate a tip’s wettability. In this case, it is necessary to use Tip Tinners for a more powerful cleaning of the oxidized tip.

- Set the temperature of the soldering iron between 250°C and 300°C.

- Dip the tip into the tinner making sure that the entire oxidized surface is in contact with the re-tinning product.

- Once the re-tinning product melts around the tip, hold it for several seconds and then clean the tip using dry cleaning methods like brass wool or an automatic tip cleaner.

Repeat steps 2 and 3 until the oxidation has been completely removed and the tip shows a good wetting on all its working area. Flux residue on the chrome section of the tip

There is no need to clean black flux residue from chrome surface of a tip. It is just unattractive but it does not affect soldering performance or tip integrity.

If you try to remove this residue using brushes you are going to erode the iron under the tinned surface unnecessarily.

Remember to avoid bad habits and take just one more precaution to prevent oxidation of the tips: deposit a layer of solder which completely covers the working area of the tip after each cleaning and before returning the tool to the stand.

Look after your tip and you will get better results!

Thank you, admin, to explain the full process of removing oxidation from tips. This procedure is working practically for me also.

Thank you, James. We are happy to hear that it works for you! Please, feel free to share also your tips 🙂

Thanks for such useful information.

One thing:

Instead of writing “Repeat steps b. and c”, you should write “Repeat steps 2. and 3.” because you have numbered the points as 1,2,3 instead of a,b,c.

Hello. We are happy you found it useful. Thanks for the warning, the text is now corrected. Have a nice day!

I appreciate the breakdown. I’m learning to solder on stained glass.

Dear Azoay,

Thank you for your message. Please feel free to contact us if you ever need our support.

This removal of oxidation part is really interesting. Thanks for explaining everything about oxidation removal. Glad to read!