Ask for a test of

any JBC product

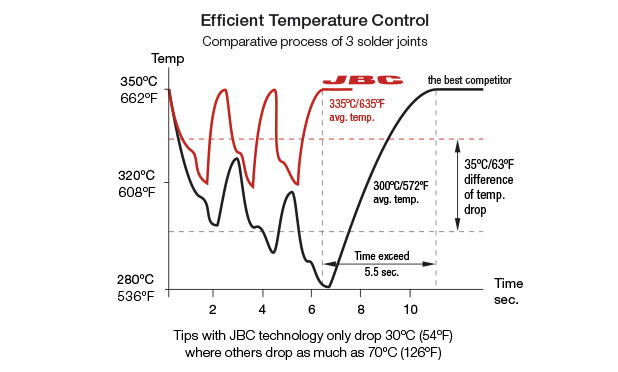

High Power / mass ration tips and integrated heater / thermocouple delivers the best thermal recovery in the market along with lower soldering temperatures.

● Tips with JBC technology only drop 30ºC (54ºF) where others drop as much as 70ºC (126ºF).

● This innovative technology allows a reduction of the temperature by at least 50ºC (90ºF).

● Lower temperature reduces the risk of damaging components and improves quality of soldering and desoldering.

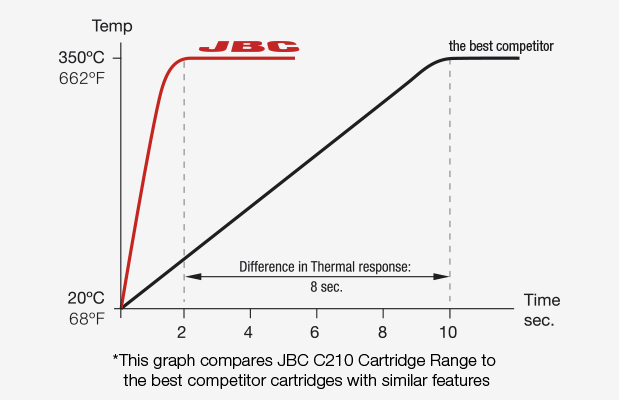

JBC Stations work with the JBC Exclusive Heating System which recovers tip temperature extremely quickly. This increases work efficiency and allows the user to work with lower temperatures.

Heating system principles:

● JBC System can reach 350ºC (662ºF) in only 2 seconds, while others need between 10 and 90 seconds.

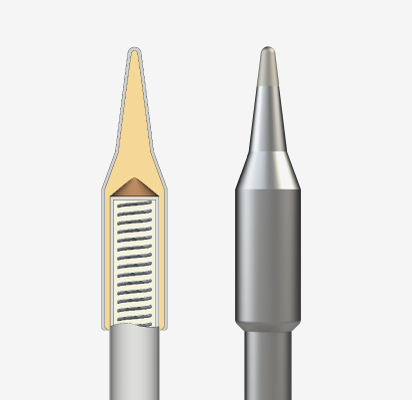

● The fully integreated thermal sensor to the heater ensures an extremely quick temperature recovery.

● The compact element optimizes heat transfer by reducing the thermal barriers.

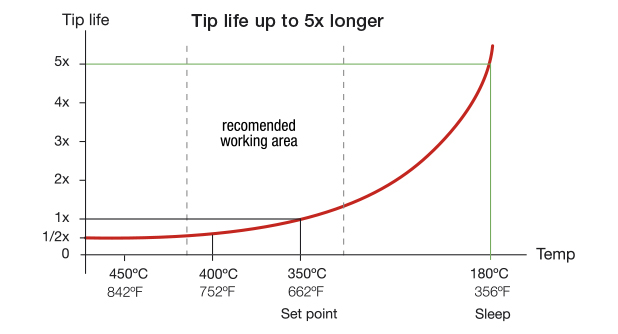

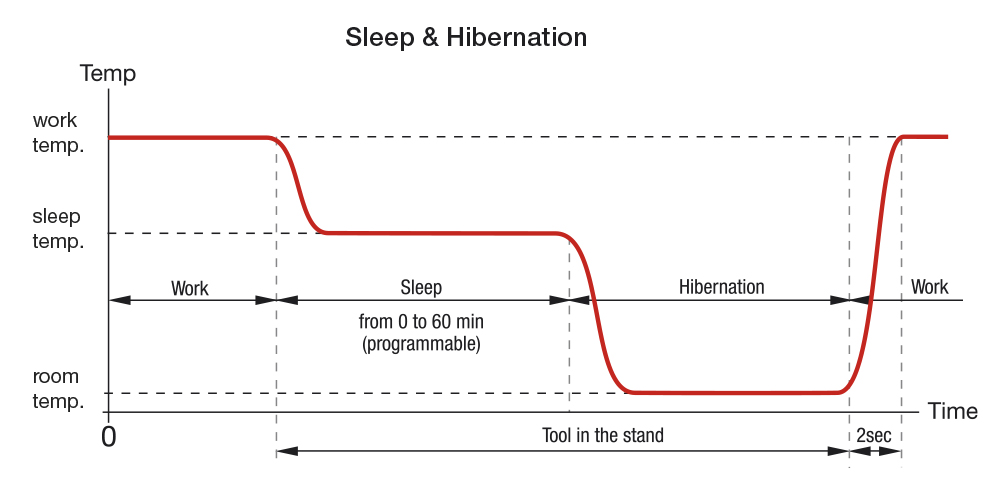

Thanks to automatic detection of the tool in the stand, JBC Soldering and Rework Stations allow the tools to enter into Sleep & Hibernation mode when not being used. As a result, tip life lasts up to 5 times longer.

Longer Tip life

Tip life increases exponentially by using lower temperatures as shown. Using the Sleep Mode, the temperature is further reduced, which extends tip life by 5.

Sleep Mode

Sleep Mode automatically lowers tip temperature below solder melting point when the tool rests in the stand.

It prevents the dissolution of the tip’s iron coating into molten solder.

Hibernation Mode

After a configurable period of tool inactivity in the stand (10 min factory default), the tool enters into Hibernation Mode.

It cuts off the power supply making the tip reach room temperature thus preventing oxidation and saving energy.

Flux and solder alloy

Too much active Flux can cause corrosion. IPC recommends: ROL, REL and ORL.

The internal flux from small Ø solder reels might not be enough. Provide compatible external Flux if necessary.

Oxidization

Iron oxide does not wet nor transfer temperature well (dewetting). The higher the temperature, the greater the risk of oxidation. Keep tips always tinned while not in use. Use flux on your solder joints. Take advantage of SLEEP & HIBERNATION functions.

● Iron plating thickness

Plate wear shortens tip life (hollowed-out). Use the cleaning methods provided by the manufacturer. Do not apply too much pressure to the tip.

● Correct techniques

Too much pressure on the surface to solder can cause tip or plate breakage. Do not use as a pointed object or a screwdriver. Choose the biggest tip possible for each application and work at the lowest possible temperature.

● Working temperatures

The higher the temperature, the greater the oxidation and corrosion. Work with the lowest possible temperature. Use thermal efficient tools and keep tips clean of oxidation.

No tools needed to change the tip. Just place in holder, pull and insert the new tip. Reduces your idle time while increasing operator safety.

● Increase productivity by using the quick cartridge extractor, which is available in all Stands and Compact Stations.

● This system designed by JBC allows the user to change cartridges quickly and safely.

● Without switching the Station off, you can carry out different soldering jobs in just few seconds.

Save time by using the quick cartridge extractor in a fast and safe way.

The essential part of the soldering iron is the tip. For this reason JBC offers a broad selection of cartridges of different sizes and shapes to choose from, according to each soldering or rework job.

JBC has developed the most advanced technology based on the following principles:

● Excellent Heat Transfer

● Instantaneous Heating-Up

● Great Durability

Does your soldering application require a special tip design?

Feel free to contact us at customtips@jbctools.com and let us customize the best tip for your process.

JBC's wide range of tools feature soldering and rework irons that guarantee maximum efficiency.

The short distance tip-to-grip allows you more control and the highest precision.

JBC tools are currently the smallest, the lightest and the most ergonomic.

Set up your personalized station according to your soldering or rework needs.

● Stackable modules save workspace.

● Fully compatible tools with all control units.

● Easy-to-use menu helps work more efficiently.

All the units incorporate JBC's exclusive heating system that increases work efficiency thanks to tip fast temperature recovery. For a basic working system, you need: 1 control unit, 1 stand, 1 tool, 1 cartridge.

The User-Friendly Menu allows you to personalize over 20 parameters to help manage the soldering process.

Set temperature limits, check usage counters, lock the station with a PIN or program Sleep & Hibernation features.

● Station Configuration

Set the station parameters according to your work needs and personalize the new functions

● Tools Preset

Set the tool configuration. The settings are independent for each tool type and Port

● Partial Counters

Display the cycles and the time worked

● Graphics

Analysis of the soldering process It helps you select the best tip for your work and see the quality of each soldering joint

Monitor your work with power and temperature data in real time

JBC Technology allows you to configure and manage all your JBC stations connected to your PC.

More than 95 years of experience have placed JBC at the technological forefront of tools for soldering and rework operations in electronics.

Innovation, efficiency and reliability are the key features of a wide range of products which have been designed to satisfy the most demanding requirements of professionals.

QST libraries which allows you to manage JBC soldering stations. This solution allows you to access station data remotely, using the company network and/or internet from any device, smartphone, tablet, Android, iPhone/iPad or computer.

QST Libraries

The JBC QST libraries allows you to monitor and configure JBC stations.

Connections

You can manage all the stations connected by USB to your PC.

Station Controller

The stations are controlled by the JBC Station Controller Service installed in your PC.

Innovation, efficiency and reliability are the key features of a wide range of products which have been designed to satisfy the most demanding requirements of professionals.

The R&D department create the most innovative soldering technologies thinking in your company's needs.

JBC has the solution for those customers who want to have full traceability of their processes during the manual soldering operations, providing tools to control, monitor and trace the soldering process of JBC Stations.

This website uses own and third-party technical, analysis and advertising cookies to anonymously facilitate browsing, customise the advertising and analyse website use statistics. We deem that by continuing to browse you accept their use. Learn more

Storage Preferences

When you visit websites, they may store or retrieve data about you using cookies and similar technologies ("cookies"). Cookies may be necessary for the basic functionality of the website as well as other purposes. You have the option of disabling certain types of cookies, although doing so may impact your experience on the website.