Ask for a test of

any JBC product

The main factors contributing to cracking Multilayer Ceramic Capacitors (MLCC) are the brittleness of the ceramic materials and the thermal and mechanical stresses associated to SMT assembly processes. During manual rework, one of the main risks for these MLCC is the thermal shock that takes place when the soldering tip touches directly the component creating cracks on it.

• Applying the soldering tip only to the pad so the heat is transferred to lead through the solder alloy.

• Preheating the chip to more than 150°C to reduce the temperature gradient that takes place as soon as the

soldering tip is applied.

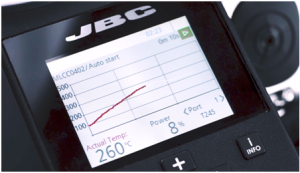

JBC Soldering introduces the final solution for reworking thermal shock sensitive components like MLCC capacitors: Dynamic Soldering Profiles for hand soldering tools.

Now, by combining the new Dynamic Temperature Profile functionality with the most precise JBC rework tools, it is possible to reliably rework MLCC capacitors as small as 008004 and other thermal shock sensitive components individually eliminating the risk of disturbing nearby components.

This website uses own and third-party technical, analysis and advertising cookies to anonymously facilitate browsing, customise the advertising and analyse website use statistics. We deem that by continuing to browse you accept their use. Learn more

Storage Preferences

When you visit websites, they may store or retrieve data about you using cookies and similar technologies ("cookies"). Cookies may be necessary for the basic functionality of the website as well as other purposes. You have the option of disabling certain types of cookies, although doing so may impact your experience on the website.