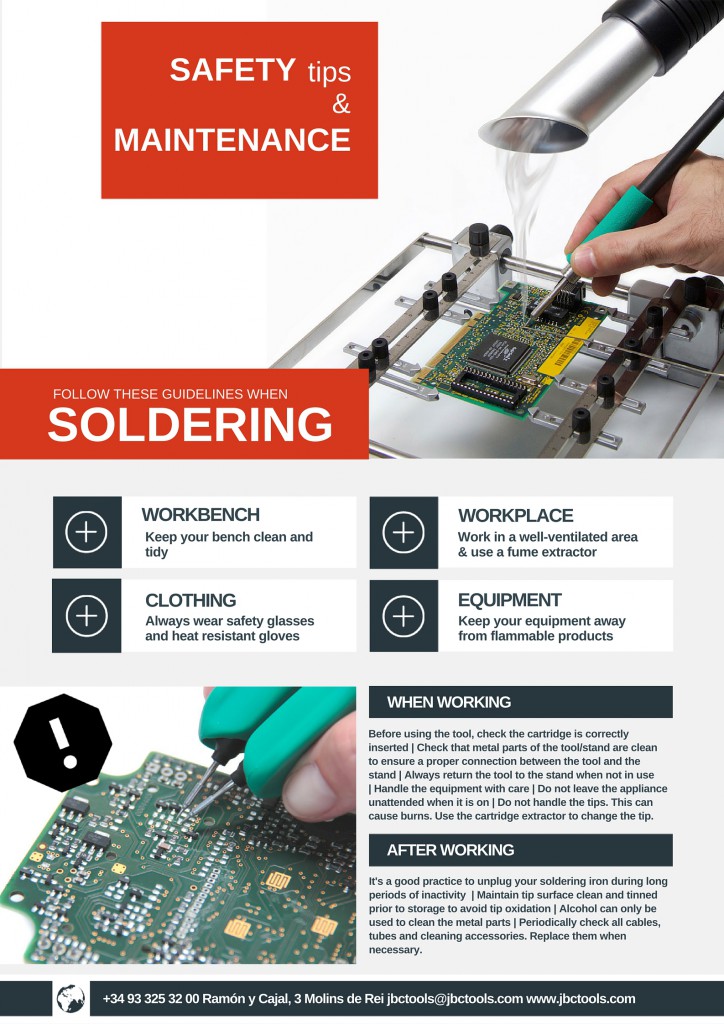

As soldering poses a few different dangers, we have prepared this safety checklist to ensure operator awareness of the hazards and good practices when working. To stay as safe as possible, read on!

Safety before working

- Workbench: Keep your bench clean and tidy.

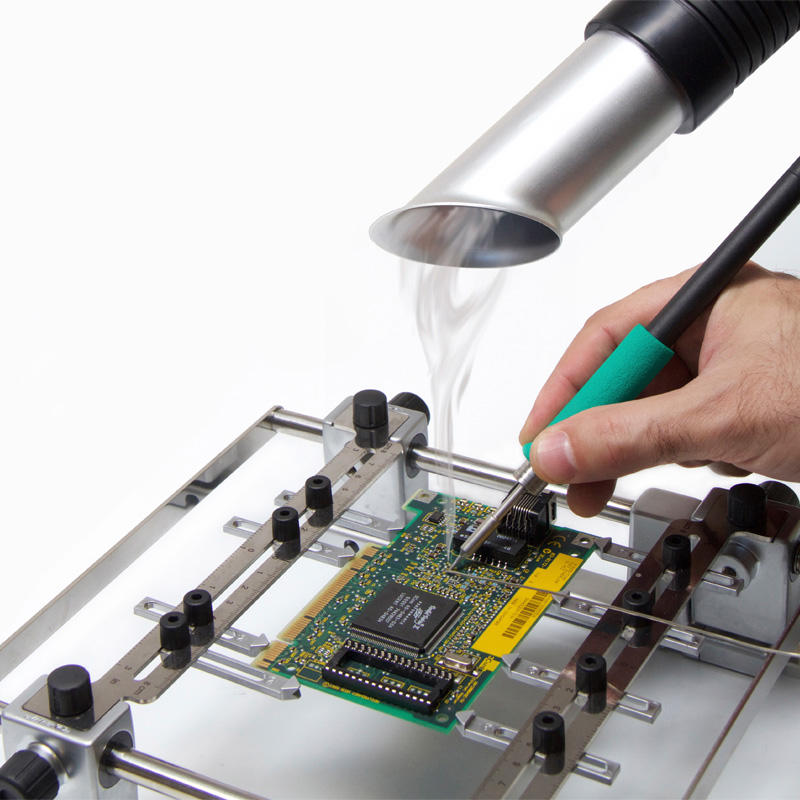

- Workplace: Work in a well-ventilated area and use a fume extractor.

- Clothing: Always wear safety glasses and heat resistant gloves.

- Equipment: Keep your equipment away from flammable products.

Safety when working

- Before using the tool, check the cartridge is correctly inserted.

- Check that metal parts of the tool/stand are clean to ensure a proper connection between the tool and the stand.

- Always return the tool to the stand when not in use.

- Handle the equipment with care.

- Do not leave the appliance unattended when it is on.

- Do not handle the tips. This can cause burns. Use the cartridge extractor to change the tip.

Safety after working – Maintenance

- It’s a good safety practice to unplug your soldering iron during long periods of inactivity.

- Maintain tip surface clean and tinned prior to storage to avoid tip oxidation.

- Alcohol can only be used to clean the metal parts.

- Periodically check all cables, tubes and cleaning accessories. Replace them when necessary.

What other safety tips would you recommend?

You can download our safety checklist. Simply click on the image below. The poster is available in PDF format.

Please like & share:

Is there any information about this subject in different languages?

Hello!

We are sorry, we always write our posts in English.

Do you want to download the “safety guidelines” poster in other language? If you provide us the translation of the text, we can update the pdf and send it to you ;-). Let us know!

Any recommendation on the specifications of the heat resistant gloves? I saw in some of your videos that the operator uses gloves but i am not sure that they are heat resistant (they appear to be thin /nit bulky).

Thank you

Hello Dimitris, thanks for your comment. We recommend wearing safeguard gloves with ESD protection. Those we use in our videos are designed for minimum risk only, are thinner so you can see the handling better. Hope that helps!

Is there any special mask that you can suggest for protection from fume extract? Particularly for individuals with respiratory problems..

Charcoal Activated Carbon Filter Masks are commonly use in the industry. We highly recommend working in a well-ventilated area and using a fume extractor.