Early soldering irons were very basic and were not very good for electronics soldering. There was no heat control and every time you placed the tip on a joint, the tip would cool down. Today’s stations have overcome these problems. But if you want to solder the right way, without getting frustrated the iron, and get professional results, read on.

Almost all stations have a menu with some parameters adjusted to maximize equipment performance and correctly manage the soldering process. Which parameters should be modified?

Just follow our recommended guidelines:

- Temperature

The wrong temperature can lead to faulty soldering, which in turn can lead to total production failure.

Normally, a JBC station’s temperature range is 90-450ºC (190-840ºF). You can change the temperature limits when working with less common applications such as low / high melting point soldering.

But be careful! In most cases, when working  with temperatures over 400°C (750°F) you can damage the PCB and its components. For example, when you are soldering and the tip is in contact with the solder joint for a short time the flux may not work properly and might seriously shorten tip life.

with temperatures over 400°C (750°F) you can damage the PCB and its components. For example, when you are soldering and the tip is in contact with the solder joint for a short time the flux may not work properly and might seriously shorten tip life.

If the solder joint requires more energy (e.g. multilayered or high dissipation boards), we strongly recommend using other aids like preheaters.

Likewise, 200ºC (392ºF) is considered to be a proper starting point for leaded applications for very small low energy demanding components. By lowering the temperature you reduce the risk of damaging components and therefore improve the quality of soldering.

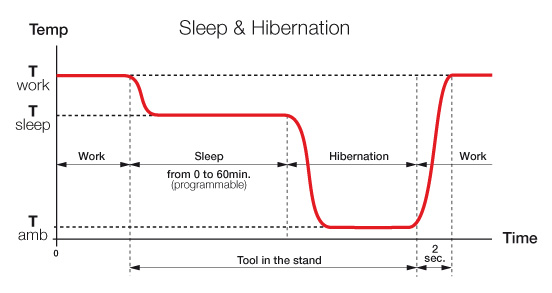

- Sleep function

The Sleep function automatically reduces tip temperature when the iron is resting in the stand. The sleep temperatures (around 180ºC – 356ºF) are usually set to achieve a balance between preventing oxidation and reaching the working temperature once the tool lifts from the stand and before the tip comes into contact with the PCB Board.

If the tools you are using reach the working temperature from the default Sleep mode in only a few seconds, as with JBC tools, the sleep delay should be preset to 0 min. Once the tool is returned to the stand the temperature will automatically drop to the sleep temperature, extending tip life and avoiding oxidation.

You should remember that setting these parameters to higher values will unnecessarily accelerate oxidation and shorten tip life especially when working with high temperatures up to 450°C (840°F).

- Hibernation mode

This function provides total protection for the tip from oxidation during long periods of inactivity while the tool is in the stand. With JBC stations, you can set the time the tool will remain at Sleep temperature before entering the Hibernation mode. This is when the power supply is cut off and the tip remains at room temperature. We recommend that the time from Sleep to Hibernation should not exceed 10 minutes.

Another good piece of advice to prevent oxidation and extend tip life is to re-tin the tip before placing it in the stand. Look after your tip and you will get better results.

Excellent blog you have shared. I don’t think there is any other simple way to know the best way of soldering. You have beautifully discussed its requirements and the tips for better soldering.Good Luck for this one.

Thank you, Chris.

Pretty informative. Thank you for sharing it. So can you please recommend some of the best JBC station models for hobbyists?

Hello Edward. Thanks for your comment. We recommend you our Compact Line. It’s a self-contained equipment (station + iron + tip cleaning system) with temperature control. All the stations incorporate the Sleep &

Hibernation features that lower tip temperature when the tool is placed on the stand. Please, check complete details here: https://www.jbctools.com/compact-category-10.html. Hope that helps!

Could you please recommend some starting soldering temperatures for lead free solder and DIP / through hole components? How many degrees higher than the lead-free solder specs should the tip be for efficient melting and solder establishment?

Also, some component (e.g. capacitor) datasheets recommend very high temperatures for hand soldering (around 360+ deg for max 3-4 seconds). Isnt this too high?

Hello! Thanks for your comment.

The special characteristic of the most common lead alloys is that the fusion temperature is about 180°C. The most common lead-free alloys have a fusion temperature of about 220°C. So the difference of 40°C meant it was necessary to increase the temperature of the solder tool to achieve a solder joint in the same length of time (if the soldering time is increased, then the components and the printed circuits may be damaged) and this reduced the life of the tips and increased oxidation.

The usual working temperature for lead-free tin alloys is 350°C. For SMD 01005-sized components one can work at lower temperatures of around 300°C because of their reduced size.

You can find more useful information on our blog >>> https://www.jbctools.com/blog/correct-temperature-soldering/.

Hope that helps!

I love this fruitful content. Thanks.

Dear,

Thank you for your positive response.

Thank you for sharing this fruitful content.